On completion of the course, holders of the Certificate of Specialisation in Mock-ups and Prototypes are able to carry out the following activities:

- preparation of the work: they analyse the documents (plans, sketches, photos, etc.) supplied by the design office or the principal. He determines the sequence of operations to be carried out, chooses the materials, organises supplies and contacts any sub-contractors;

- manufacturing the components: he makes the components of the model or prototype, either manually or by machine machining. He/she checks their shapes and dimensions;

- assembly: he/she mounts, assembles and fixes the elements obtained; he/she checks that the whole conforms to the specifications;

- finishing, coating, decoration: he/she finishes the model or prototype, applies the coating and decorations and carries out the final checks.

BC01 - Analysis and preparation of a model or prototype

- Decode, analyse the information imposed by the principal.

- Determine the purpose of the model or prototype and its application.

- Choose the materials to be used, adhesives and finishing coatings.

- Adapt a manufacturing programme according to constraints.

- Plan the supply of specific supplies.

- Suggest modifications to form and process orally or in writing.

BC02 - Making a model or prototype

Become familiar with health and safety instructions.

Determine the manufacturing processes for the model or prototype.

Organise the workstations.

Draw up the inspection procedures

Machine the components of the model or prototype (traditional MO, MOCN, specific MO):

- On manually-operated or assisted machine tools;

- On numerically-operated machine tools;

- On specific machine tools (rapid prototyping.....).

Shape the components of the model or prototype using appropriate techniques.

Mount, assemble, fix and animate the various components making up the model or prototype.

Complete the components, the assembled model or prototype to receive the final presentation coating and decoration.

Apply the final presentation coating and decorative elements.

Check the shape, dimensions and appearance of the components of the model or prototype during or at the end of production.

BC03 - Preparation, production and checking of the model or prototype carried out in the workplace

Reporting.

Machining the components of the model or prototype.(Traditional MO, MOCN, specific MO):

- On manual or assisted machine tools;

- On numerically controlled machine tools;

- On specific machine tools (rapid prototyping.....).

Shape the components of the model or prototype using appropriate techniques.

Fitting, assembling, fixing and animating the various elements making up the model or prototype.

Finishing the elements, the assembled model or prototype to receive the final presentation coating and decoration.

Applying the final presentation coating and decorative elements.

Checking the conformity of the assembled model or prototype as a whole.

Checking the appearance of the finished model or prototype against the specifications.

Find out more about this qualification (RNCP38304, exact wording of the diploma, name of the certifier, registration date of the qualification) by clicking here.

3

Positioning upstream of training entry.

Taking account of beneficiary satisfaction during and at the end of training.

Possibility of post-training support.

For beneficiaries with disabilities: possible adaptation of training and certification arrangements, support by the TH referent.

Trainers with experience in individualised learning.

Teachers certified by the French Education Nationale, Bac +3 trainers with significant experience in adult training, professional speakers.

Exams at the end of training (one-off assessment)

Evaluations during training (ECF)

Control during training (CCF)

Interview with a professional jury

Possibility of validating one or more blocks of skills

Positioning test by appointment.

Interview by appointment.

Applications on Parcoursup.

Training is available between 15 and 45 days before the start of the course, depending on the funder. Please contact us.

Contact Ms ROUBIEU Lisa

Exercise the profession of model maker-prototypist in industrial companies (automotive, aeronautical, shipbuilding, household appliances), cultural companies, museums, architectural firms.

Access for people with disabilities

Accessible to people with disabilitiesTransport

direction sous préfecture

establishment located on the plateau des bolles bordering the pond

1st apprenticeship session so no history

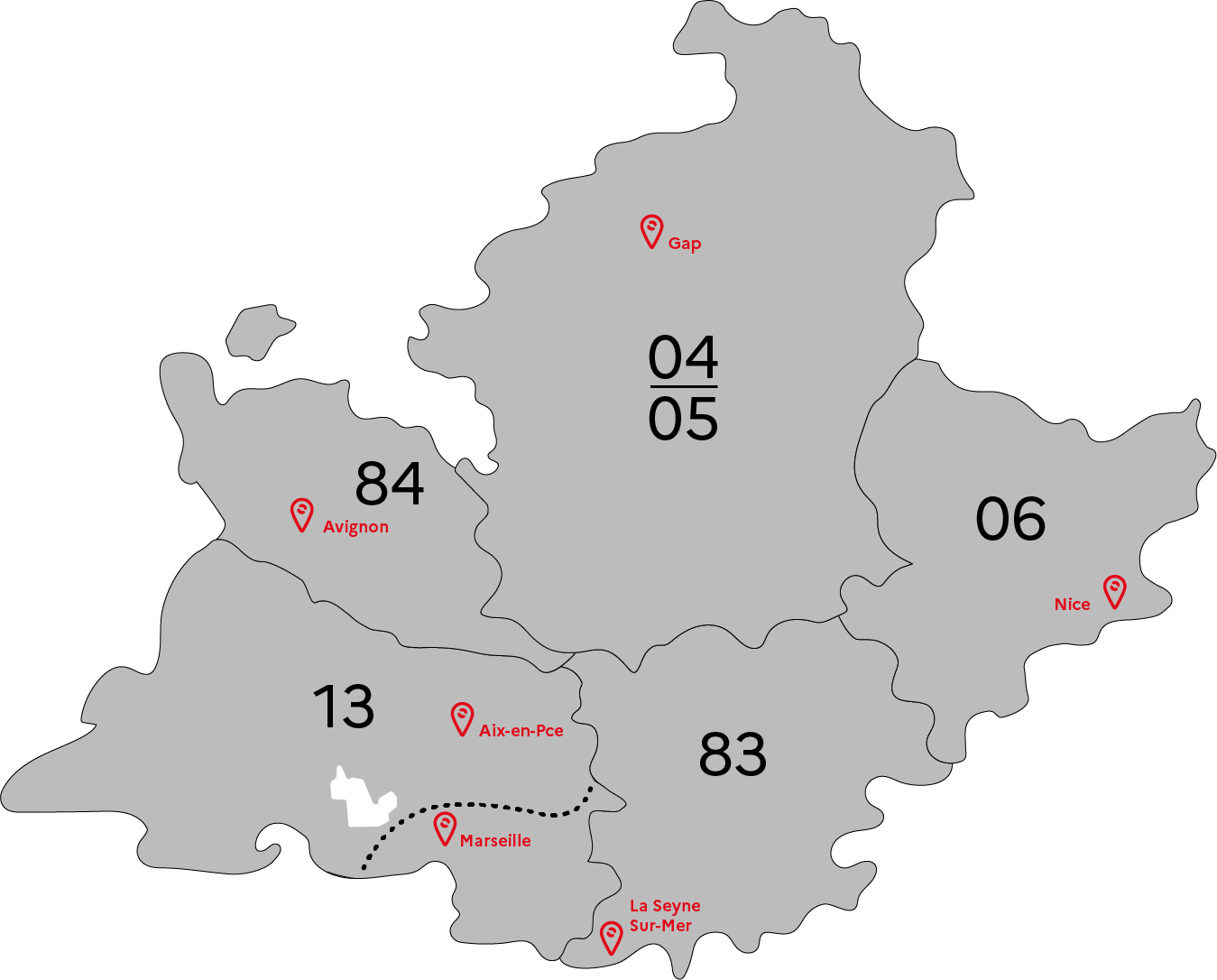

GRETA-CFA Provence

GRETA-CFA Provence

FORPRO-PACA

Réseau Formation Professionnelle

de l'Éducation nationale

FORPRO-PACA IS HIRING

LINKS