At the end of their training, mechanical product manufacturing technicians will be able to:

- manufacture parts (either in very large, large, medium or small series, or as individual parts) intended for tooling or industrial subassemblies for consumer goods for the general public, capital goods for companies.

- understand the operation and kinematics of production resources, the associated manufacturing and assembly techniques and the characteristics of the materials worked.

- mobilise digital tools and specialised software (time calculation for production management, compliance with planning, notions of production-related costs, editing of metrology control reports..)

- write and distribute production reports internally within the company, in digital form, demonstrating a command of the language, respecting the procedures installed.

- work in compliance with safety rules and instructions (Quality Hygiene Health Environment), anticipate and manage risk.

- appropriate information, technical data in a modern foreign language,

- work as part of a team and with respect for the environment.

BC01 - Study and preparation of the production

Find information in technical documentation

Interpret and check data

Prepare the production of all or part of a mechanical assembly or product or tooling

BC02 - Project for the production of products or tooling

Configure and adjust workstations

Implement a means of production

Exploits from technical documentation

. Project to produce products or tooling

Configure and adjust workstations

Implement a means of production

Exploit a production or maintenance schedule

Assemble the components of all or part of a mechanical assembly

Choose the means of handling and carry out handling

BC04 - Production and maintenance monitoring

Formulate and pass on information, communicate in written and oral form

Be involved in a professional environment, work as part of a team

Control and monitor production or tooling

Perform maintenance on means of production or tooling

Apply procedures relating to quality, safety and respect for the environment

BC06 - Mathematics

BC07 - Physics - chemistry

BC08 - Economics - management

BC09 - Prevention - Health - Environment

BC10 - Modern language

BC11 - French

BC12 - History-geography - Moral and civic education

BC13 - Applied arts and artistic culture

BC14 - Physical and sports education (for apprentices)

.Find out more about this qualification (RNCP41015, exact wording of the diploma, name of the certifier, registration date of the qualification) by clicking here.

BEP, CAP in the field or first general or equivalent professional experience.

12 people

Positioning prior to entry into training.

Interviews, remediation with the educational referent and/or company referent during training.

Taking into account beneficiary satisfaction during and at the end of training.

For beneficiaries with disabilities: possible adaptation of training and certification methods, support by the GRETA-CFA TH referent.

In order to improve the quality of our service, you can send us your suggestions or complaints using the form available on our website.

Education Nationale certified teachers, Bac +3 trainers with significant experience in adult education, professional lecturers.

Tests at the end of training (one-off assessment)

In-course assessment (CCF)

Professional portfolio

Positioning test by appointment.

Interview by appointment.

- Integration into employment in industrial companies in the mechanical engineering field of very different sizes (VSEs, SMIs, SMEs, groups or large industrial companies) positioned in very open markets affecting the mechanical engineering, agri-food, automotive, aerospace, chemical, petrochemical and pharmaceutical, energy production, building and public works, agricultural machinery, industrial maintenance, arts and crafts industries ...

- Integration into very large, large or medium series production positions for bar turning parts, aerospace parts, forging and casting parts, parts from additive manufacturing processes.

And on jobs producing single parts or parts produced in small series: workpiece holders, tool holders, inspection tooling, spare parts.

To occupy jobs as: Turner, Milling machine operator, Machinist, NC machine production technician / machinist, Bar turner, NC bar turner setter, Tool maker, Mould maker tool maker, Mechanic tool maker, Mechanic fitter, Lathe fitter fitter.

Access for people with disabilities

Accessible to people with disabilitiesTransport

Satisfaction rate: 94% out of 4 people who responded to our satisfaction survey

Overall rate of integration into employment: 25%

Rate of integration into the target profession: 25%

Rate of recommendation: 94% out of 4 people who responded to our satisfaction survey

Study continuation rate: 75%

Rate of terminated apprenticeship contracts: 20%

Added value of the establishment : Technical facilities in machining and dedicated room equipped with IT.

Our indicators can be consulted on the website : cliquez ici

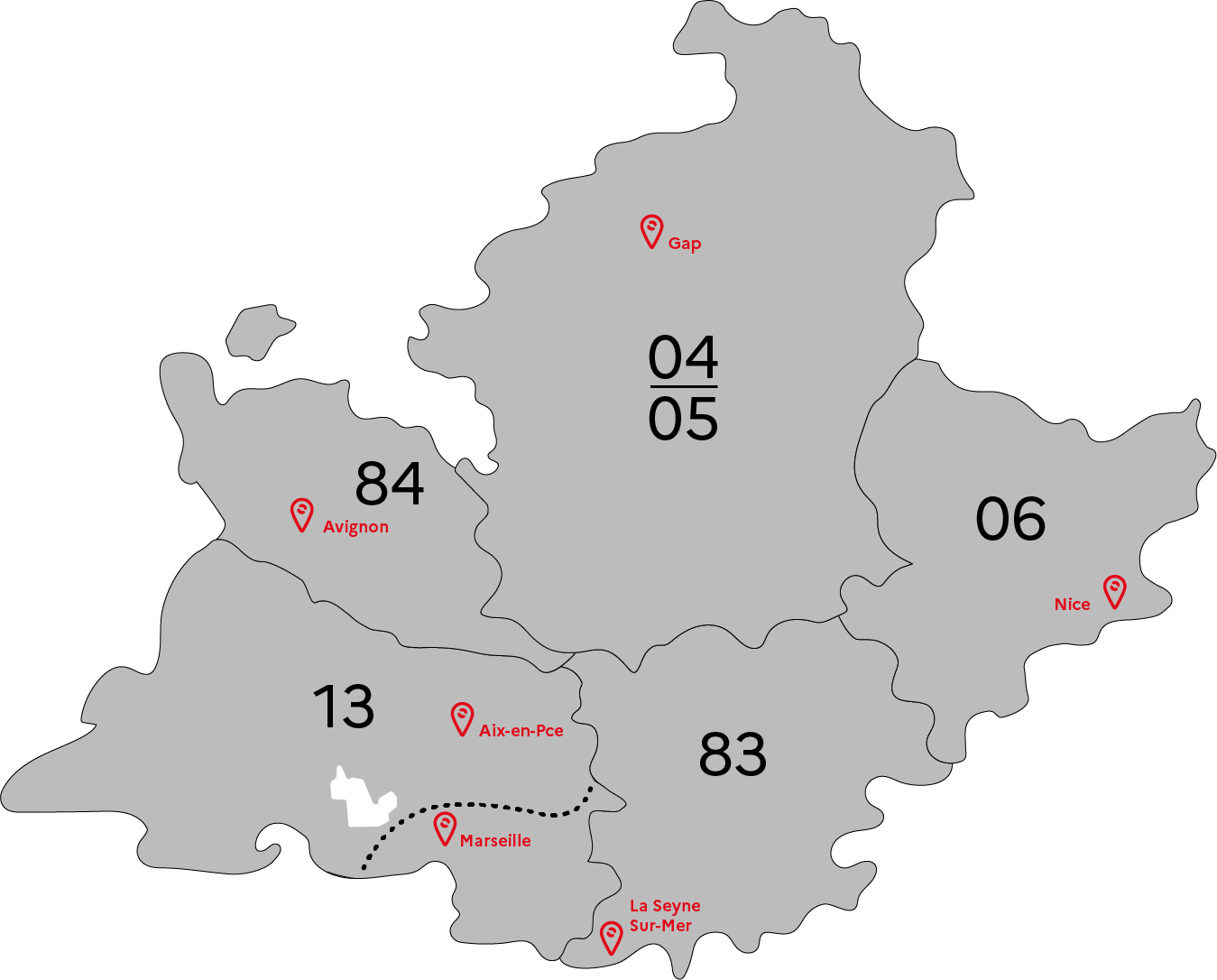

GRETA-CFA Provence

GRETA-CFA Provence

FORPRO-PACA

Réseau Formation Professionnelle

de l'Éducation nationale

FORPRO-PACA IS HIRING

LINKS